Metal Shop

Accessing the Metal Shop

Step 1: Get certified!

Before using the Metal Shop, you’ll need to complete either a Metal Tools Fast Track assessment (for experienced makers) or a Metal Tools Level 1 class to get certified. This ensures everyone in the space is trained and working safely.

Step 2: Get a Membership

Once certified, choose the access option that works best for you! Whether you want full monthly membership access or prefer a more flexible punch pass; weekend, weekday or all-week. We’ve got options to fit your needs.

Step 3: Get Making

With certification and membership in place, you’re ready to start creating! Book time on equipment, join community events, and bring your projects to life in a well-equipped, collaborative Woodshop space.

Tools & Equipment

-

Sandblasting Cabinet

Blast abrasive media at high pressure to clean and texture metal surfaces

-

Mig welder

Fuse metal parts with controlled wire-feed welding for strong, versatile joints

-

tig welder

Produce high-quality, low-spatter welds with precise tungsten electrode control

-

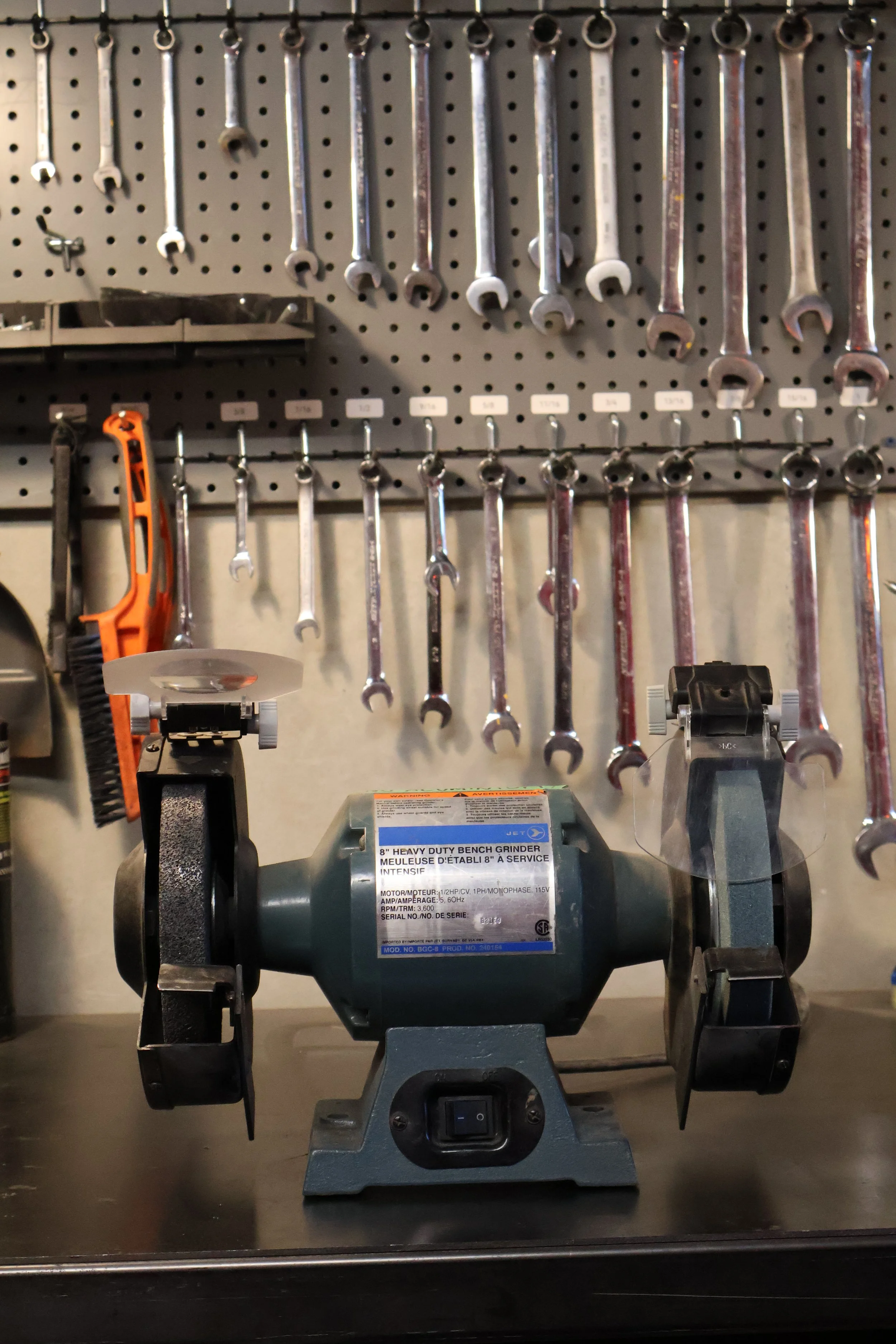

bench grinder

Grind and sharpen tools or remove burrs with high-speed abrasive wheels

-

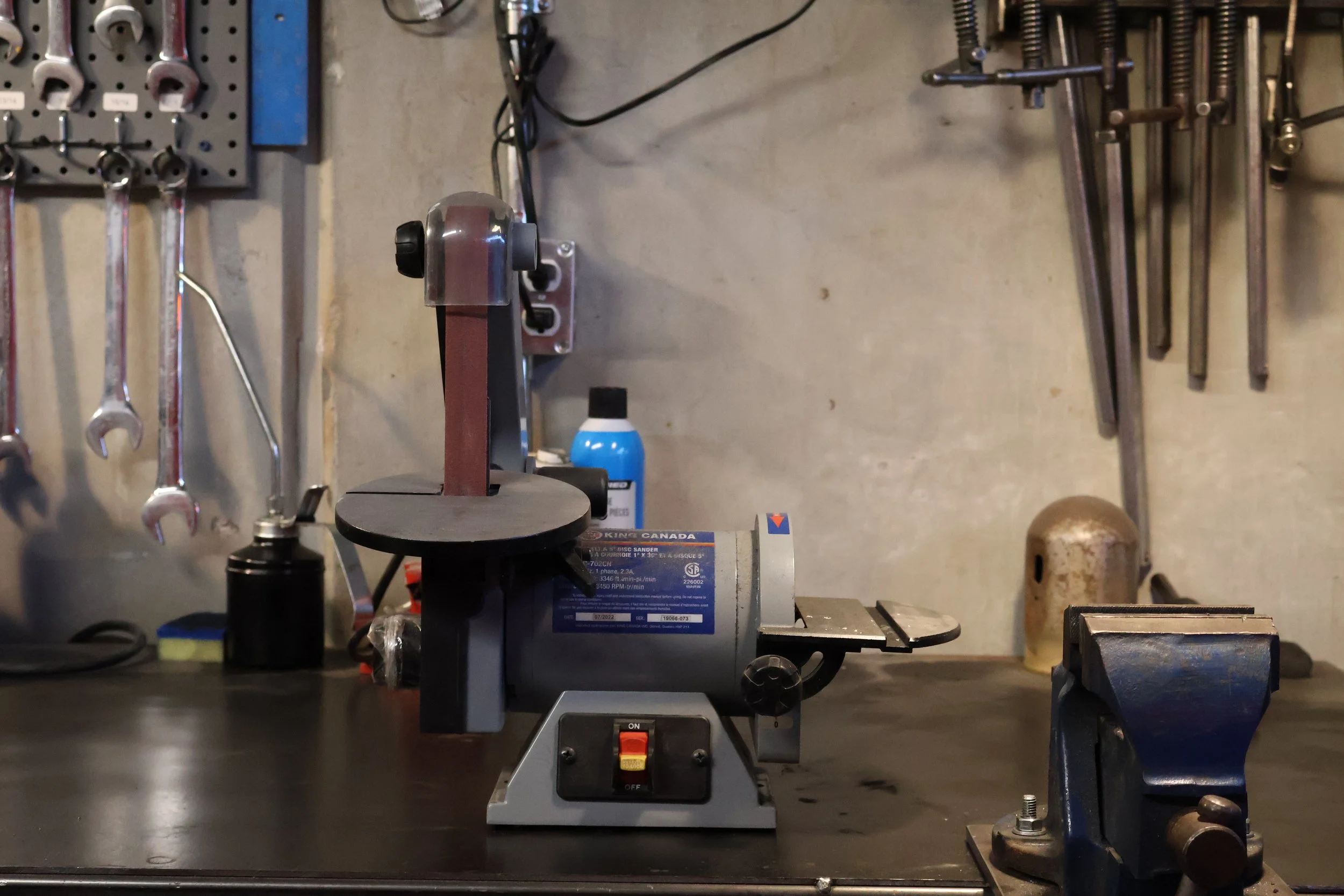

belt & disc sander

Shape and finish surfaces with combined belt sanding speed and disc sanding precision

-

1o" sharpener

Sharpen blades and tools to a razor edge with a stable 10″ grinding wheel

-

delta 16 1/2" drill press

Drill holes up to 16½″ deep with precise variable-speed vertical drilling

-

14" Multicutter

Tackle curves, bevels, and joinery cuts with a versatile 14″ multi-blade cutting system

-

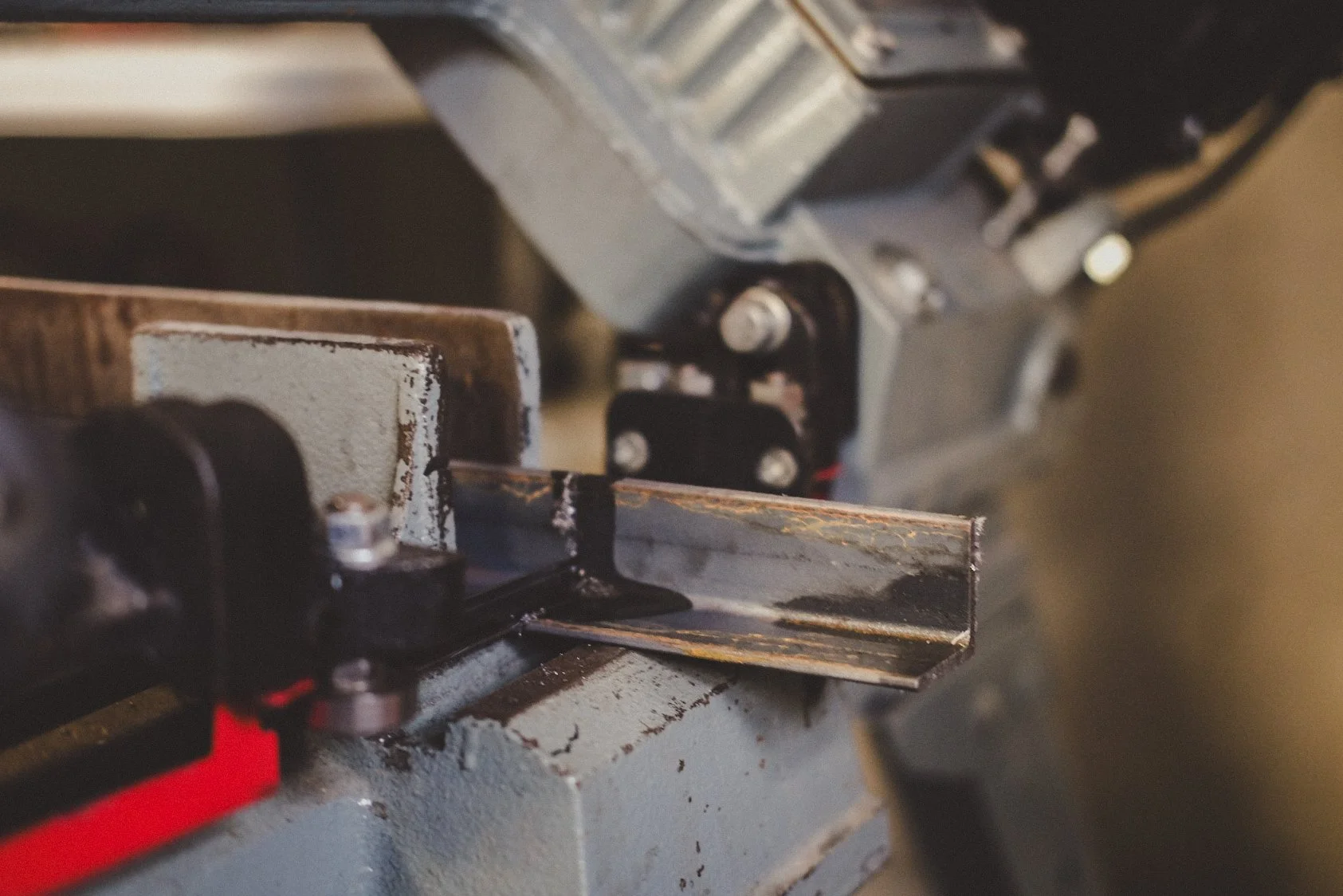

horizontal band saw

Cut metal stock accurately with a horizontal blade and steady clamping system

-

Hand Tools

Essential spanners, hammers, grinders, screwdrivers and much more

Metalworking Classes

Whether you’re curious about cutting metal or ready to expand your maker skills by learning how to weld, our metalworking classes are a great way to create something strong, functional, and built to last.